Introduction to outdoor energy storage power supply materials of Jiechuangxin Materials

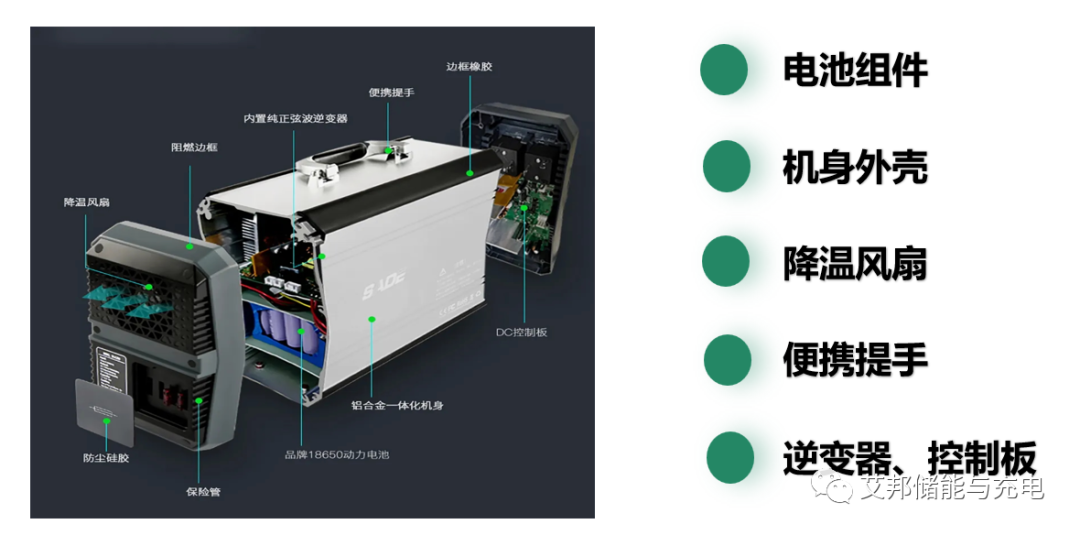

Outdoor energy storage power supply

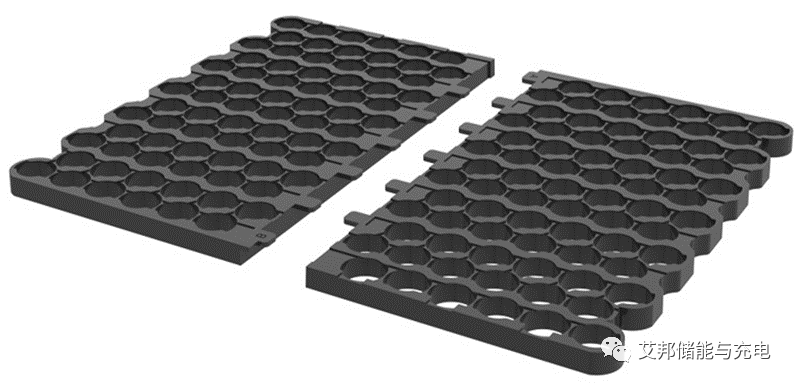

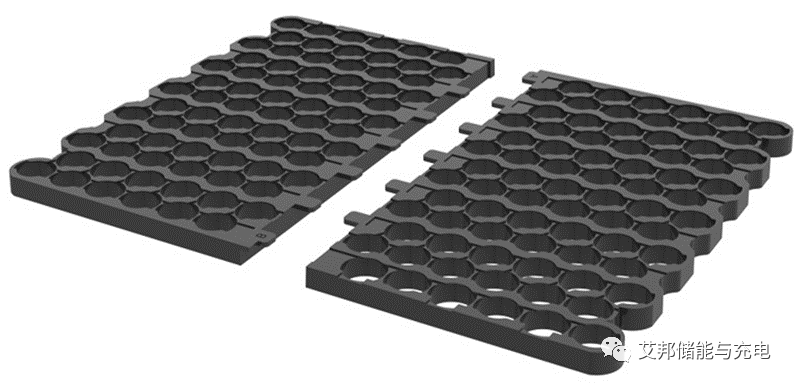

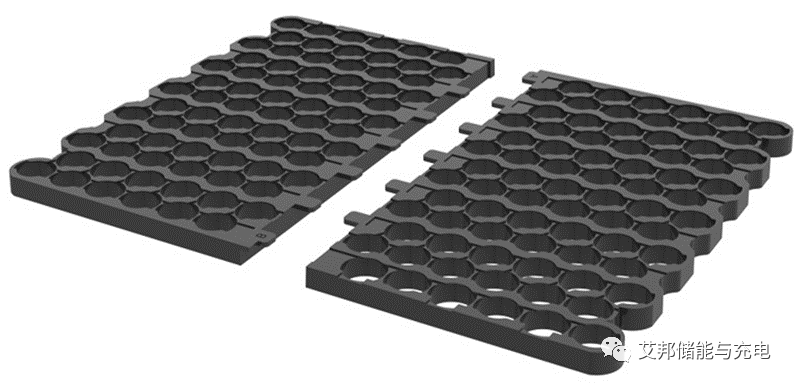

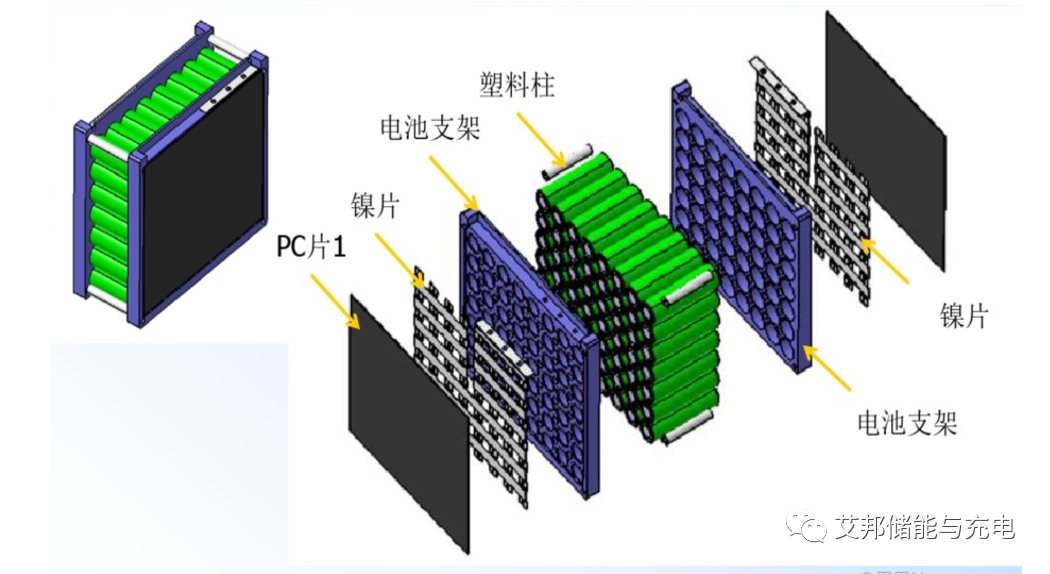

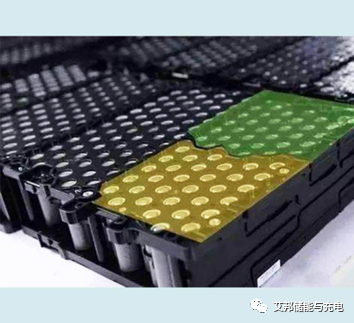

Battery pack bracket

The battery pack bracket is a fixed bracket for installing the battery, which plays the role of fixing the battery cell and clamping protection. If there is no bracket for fixing, after spot welding the battery cell with nickel strip, the finished product vibration may tear off the nickel strip.

The materials of battery fixing bracket shall be flame retardant, high strength, high toughness, high CTI value, etc.

1)Light support material scheme: halogen-free flame retardant PC/ABS

Flame retardant PC/ABS alloy can achieve heat resistance of 90-105 ℃ through formula adjustment, and has the following advantages:

Halogen free flame retardant, green and environment-friendly, meeting UL94 V0 standard;

Good impact resistance, not easy to crack when falling;

Good fluidity, easy to process and shape.

2)Heavy support material scheme: halogen-free flame retardant reinforced PBT

Polybutylene terephthalate (PBT) itself has the characteristics of thermal stability, solvent resistance, and excellent electrical insulation in humid environment. The material reinforced and modified by halogen-free flame retardant glass fiber has the following advantages:

Considering both strength and toughness, the product performance remains stable under high temperature and high humidity environment;

Halogen free flame retardant, green and environment-friendly, meeting UL94 V0 standard;

Excellent electrical insulation performance, CTI ≥ 400V;

Very good fluidity, suitable for thin-wall injection molding of complex structures.

3)Recommended scheme: thermal conductive flame retardant nylon

The plastic itself has poor thermal conductivity. High power batteries generate a lot of heat in use. If the heat cannot be diffused in time, the use of the battery will be affected, causing potential safety hazards.

By heat conduction modification of nylon, strength and electrical insulation are considered at the same time. The material has the following characteristics:

Good heat conduction and fast heat dissipation;

Both strength and toughness shall be considered, and it shall be stable at high temperature;

Excellent electrical insulation performance, CTI ≥ 600V.

2.Battery shell material

The use scenario of outdoor energy storage battery requires frequent handling and moving, so the battery shell must have a certain resistance to drop damage, and at the same time, it can withstand the damage of outdoor ultraviolet rays, with high retention rate of color and mechanical properties. Considering that the size of single shell parts is relatively large, the ease of processing is also important.

Scheme I PC/ABS 0811F:

Excellent flame retardancy and safety, conforming to UL94 V0 standard;

Scheme II PC/ABS 0811F-U:

Good weather resistance, excellent appearance and color for 5 years outdoors, flame retardant, and fall resistant;

3.Portable handle materials

Scheme I PC/ABS 0811: Ordinary bearing

Scheme II PA6 0562: good load bearing and good surface effect

Scheme III TPE 1210: adhesive coating, skin like touch, weather resistance and durability

1)New energy battery module materials

Scheme I PA66 0662F: 30% glass fiber reinforced halogen-free flame retardant nylon 66

Scheme II PBT 0462F:30% glass fiber reinforced halogen-free flame retardant PBT

Excellent flame retardant GWFI: 800 ℃;

Good electrical performance, CTI>400V;

Stable size, low warpage;

High temperature resistance without deformation.

2.)Battery dust cover material

PC 0210F-S (plate):

Hunan Jielikang Technology Co., Ltd

In 2021, the newly added company in China will be affiliated to the listed company Shenzhen Jiechuangxin Materials Co., Ltd., with a registered capital of 10 million yuan and a plant area of 8000 m2. It will be a scientific and technological company focusing on the R&D, production, sales and service of new polymer materials. In the first phase, 10 automatic twin-screw extrusion production lines will be put into operation, with an annual capacity of 20000 tons. Later, it is planned to have an annual capacity of 50000 tons. It has a first-class R&D, production and marketing team. The R&D center is located in Shenzhen, Guangdong, and the production base is located in Yiyang, Hunan.

1. Passed ISO9001: 2015 quality management system certification

2. Passed ISO14001:2015 environmental management system certification

3. The product complies with the European Union ROHS directive and has obtained the US UL certification

4. Passed IATF16949:2016 Automotive Industry System Certification

National scientific and technological enterprises

Director of Hunan New Material Industry Association

Brand with reliable quality in engineering plastics industry

It has a first-class R&D team and independent knowledge industry, and has obtained a number of invention patents

Won the third prize of the Maker Group in the 2021 "Maker China" Hunan Innovation and Entrepreneurship Competition

Strong executive power

Deep understanding of the project

Strong quality control ability

After sales service is considerate and customer first

Rich modification technologies

Glass fiber and carbon fiber reinforced modification

Toughened and cold resistant modification

Flame retardant modification

Alloying modification

Weathering modification

Conductive and thermal conductive functional modification

Contact: Gan Haojun 13924643976

e-mail address: ganhaojun@szjcxc.com

Tel: +86 755 3318 0518

Fax: +86 755 3318 0561

R&D Marketing Center: Songgang Hongrongfa Industrial Zone, Bao'an District, Shenzhen

Manufacturing base: Nanxian Economic Development Zone, Yiyang City, Hunan Province